- Get link

- X

- Other Apps

Irrespective of the technology choosing the right compressor for your application is very critical. A higher PSI means that your device can store more air allowing it to operate longer.

Air Compressor Buying Guide Which One Do I Need

Air Compressor Buying Guide Which One Do I Need

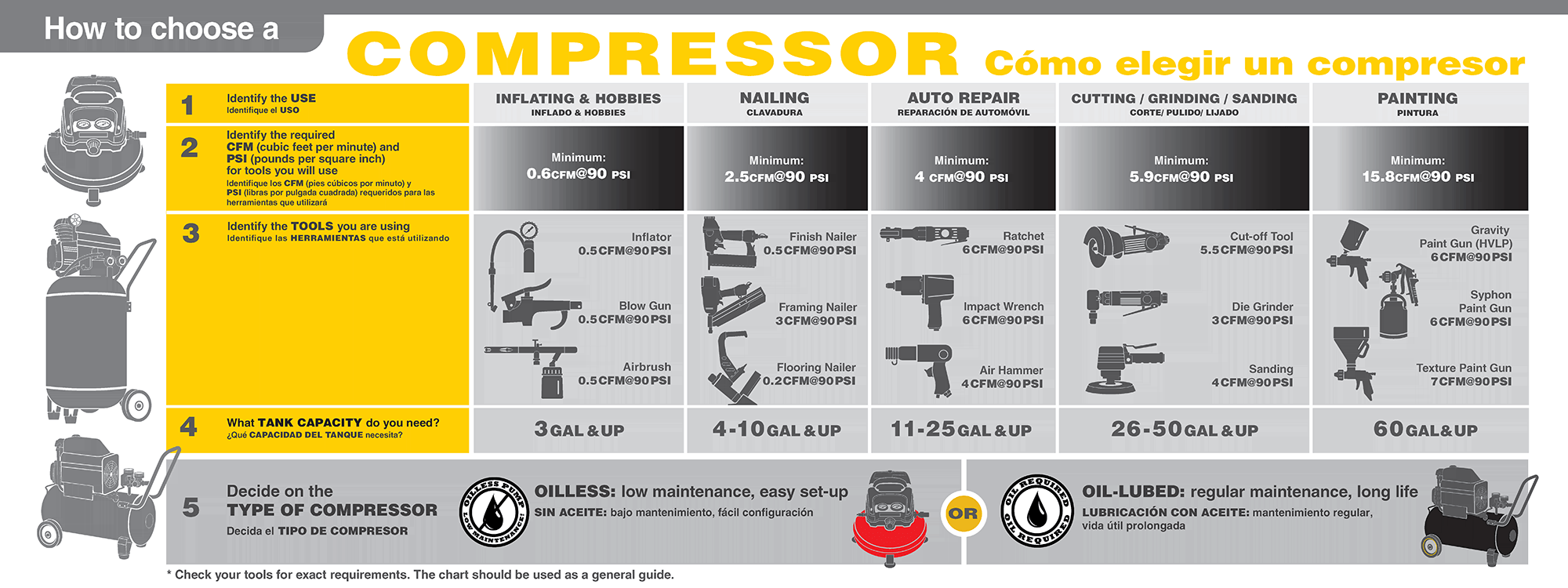

Sizing an air compressor requires a logical sequence of steps to determine the proper amount of air for the application.

How to choose an air compressor. Its a real cats cradle. But if you want to leave open the possibility of additional tools without buying a second compressor consider a more powerful compressor up front. That means if the compressor has a 10 CFM rating it can release 10 cubic feet of air in a minute.

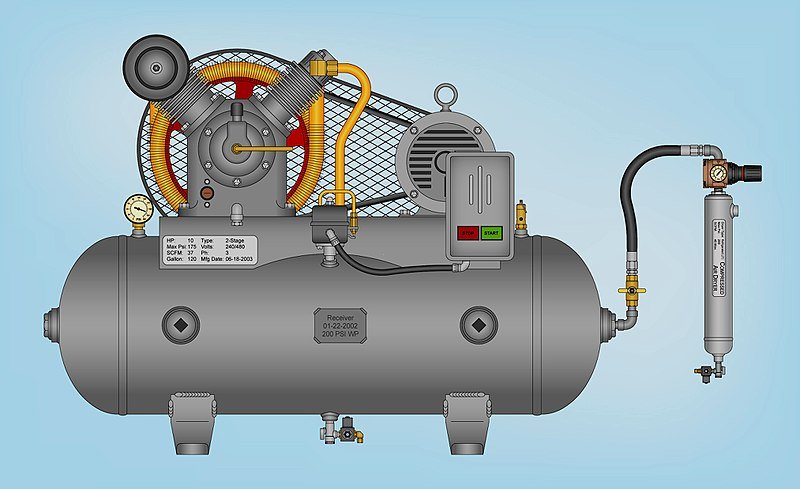

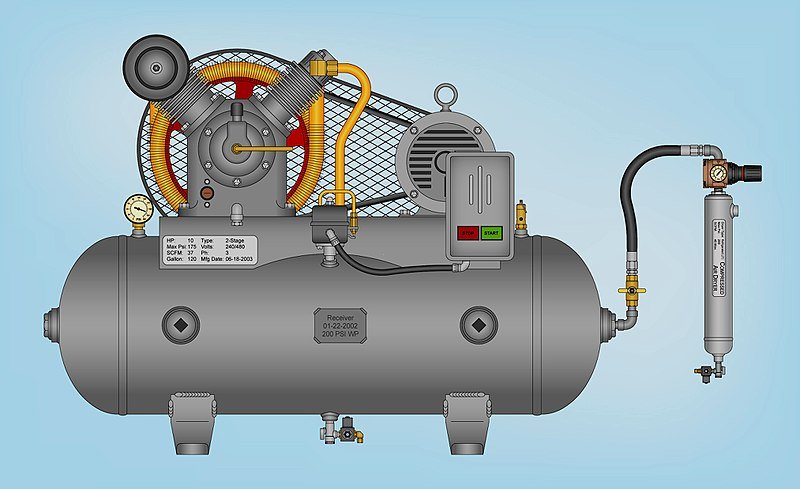

There are plenty of situations when you cant do without an air compressor. Many industrial compressors are two-stage which means they build up to shut-off pressure in two stages. Choosing a tank size With tank sizes ranging from 6 litres to 500 litres choosing the perfect capacity air tank receiver will seriously affect the performance of your compressor.

Before choosing an air compressor you must determine the CFM and PSI which the air tools need. Demand for air compressors keeps growing an increasing number of power tools require it. The higher the HP of the compressor the greater the PSI.

Choosing the right compressor for your job is a decision tha. Based on CFM and PSI we measure the effectiveness of an air compressor on various circumstances. The first stage builds to about 90 PSI and the second stage builds to 175 PSI.

Well tell you what they mean what matters and what doesnt and help you choose a. Use the chart below to determine your average CFM requirements per tool or check with the manufacturer. Tools manufacturer assigns the required CFM and PSI.

Most air tools require 90 PSI to run properly but to maintain 90 PSI at the tool you need a compressor with a higher shut-off pressure. This will give the compressor some room for future expansion or heavier tool use. To find the minimum tank size of the compressor you need multiple your tools required SCFM by 6.

Be sure to consider the tools youll be using. In order to choose the right air compressor you must first determine the frequency of use according to the compressed air requirement of your application. But dont let all those specs confuse you.

The overall air volume a compressor can generate is measured in cubic feet per minute CFM and this is often the most important factor in choosing the right one to power all your tools. The following lays out a systematic approach for making the right decision. In fact choosing an industrial air compressor really comes down to just two main topics.

Add 50 to the required CFM for a margin of safety and look for a compressor that meets the requirement. When youre shopping for a small air compressor the first thing youll notice is that theyre plastered with specifications. Featuresand the quality of eachalso should be.

Once the maximum air pressure is reached PSI the duty cycle is complete. At the same time choosing an air compressor is not easy. Cubic feet per minute CFM CFM is the amount of air the compressor can produce.

Step 1 Determine your air requirements. This video describes the process of selecting an air compressor for your particular application. When you use one device with the compressor select the top CFM and PSI requirement tool.

All air tools have a cubic feet per minute CFM rating and the air compressor you choose should be able to produce enough air to get the job done. An air compressor generates compressed air that can activate various tools and mechanisms. There are many types but the most common types are listed below.

2 hp 3 gallon 28 cfm 130 psi 73 dB. For example if you run an impact wrench 8 SCFM. With regard to size compressor capacity and operating pressure take the forefront.

Additionally if you plan on using multiple tools add the CFM of each tool to decide on the size air compressor you need. Determine which one requires the highest CFM at the highest PSI. You will also need to know if the compressor should be transportable or if it will be installed in one place.

When choosing an air compressor consider the tools you want it to power. With piston compressors there are two alternatives belt drive and direct drive. First find the tool that requires the greatest amount of scfm and multiply that number by 15.

If a compressor dedicated to your nailer or stapler is what you wantand you might because that air compressor is likely to be especially portablethen the bundle is a good choice. There are several steps you can take to select the appropriate air compressor based upon your tools. This will optimise the performance and save money in terms of energy maintenance and service.

How To Choose An Air Compressor For Painting Carpenter Kit

How To Choose The Best 220 Volt Air Compressor By Samstores Issuu

How To Choose The Best 220 Volt Air Compressor By Samstores Issuu

How To Select An Air Compressor Quincy Compressor

How To Select An Air Compressor Quincy Compressor

How To Choose An Air Compressor For Your Automotive Workshop Or Home

How To Choose An Air Compressor For Your Automotive Workshop Or Home

How To Choose An Air Compressor 7 Steps With Pictures Wikihow

How To Choose An Air Compressor 7 Steps With Pictures Wikihow

How To Choose An Air Compressor In 5 Questions

How To Choose An Air Compressor In 5 Questions

Best Air Compressors How To Choose One For Yourself

Best Air Compressors How To Choose One For Yourself

How To Choose An Air Compressor 7 Steps With Pictures Wikihow

How To Choose An Air Compressor 7 Steps With Pictures Wikihow

How To Choose An Air Compressor World Inside Pictures

How To Choose An Air Compressor World Inside Pictures

Very Interesting Article This Will Show You Exactly How To Choose The Right Air Compressor According To Air Compressor Portable Air Compressor Compressed Air

Very Interesting Article This Will Show You Exactly How To Choose The Right Air Compressor According To Air Compressor Portable Air Compressor Compressed Air

How To Choose An Air Compressor Denyo United Machinery

How To Choose An Air Compressor Denyo United Machinery

How To Choose And Use An Air Compressor This Old House Youtube

How To Choose And Use An Air Compressor This Old House Youtube

How To Choose An Air Compressor Canonress

How To Choose An Air Compressor Canonress

Comments

Post a Comment