- Get link

- X

- Other Apps

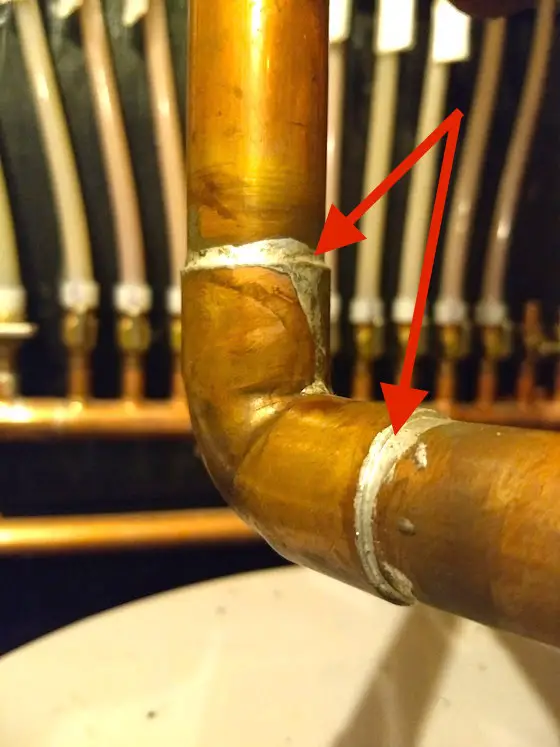

However it will require a higher melting point than a 5050 solder. Can You Overheat Copper Pipe When Soldering.

How To Solder Copper Pipe In A Wall Complete Guide Got2learn Youtube

How To Solder Copper Pipe In A Wall Complete Guide Got2learn Youtube

Then it is to be applied to the corroded areas of the pipes.

Solder copper pipe. Overall too much heat can lead to your copper pipes being damaged and the flux dissolving. Cost to do it yourself. Lead Free solder for potable water pipe Flux.

Repairing a hole in a copper pipe is a temporary fix. When youre done soldering dissolve the plug by holding the torch under the spot where the plug is. The solder for this is often 5050 solder and contains lead.

Soldering a joint in pipes that contain even tiny amounts of water is nearly impossible. The solder will melt right into the joint. How to Solder Old Copper Pipe.

How to Solder or sweat to connect copper pipes for water supply lines. The heat should be applied as evenly as possible around the fitting. With the right tools it takes a couple of minutes to solder the copper pipe.

Soldering the old copper pipes will require the removal of dirt and the corrosive layer on them. Although soldering copper pipes might sound straightforward due to the safety risks involved its always advised to hire a qualified professional to undertake these works. To connect copper tubing and pipe one of the best methods is to use solder and a.

Inspection mirror To clean the Pipe use wire wool or a kitchen pad and a good acid. But not too hot or youll burn the flux and oxidize the copper at which point you. It is used in covering the cleaned copper surfaces to be soldered before heating and assembly.

Cost to hire a professional You can expect to pay a plumbers hourly rate which is an average of 20 40 per hour. What Type of Solder is Used for Copper Pipe. How Do You Store Solder.

Stop the trickle of water with a pipe plug. From soldering copper pipe to cutting it we have the best content that will make it super easy for you to handle this task. For potable water systems lead-free solid core solder must be used.

Follow all insights detailed here to best solder and also cut the copper pipe. It will be free of elements you dont want entering your drinking water. The following article explains the process of soldering copper pipes and the necessary materials required.

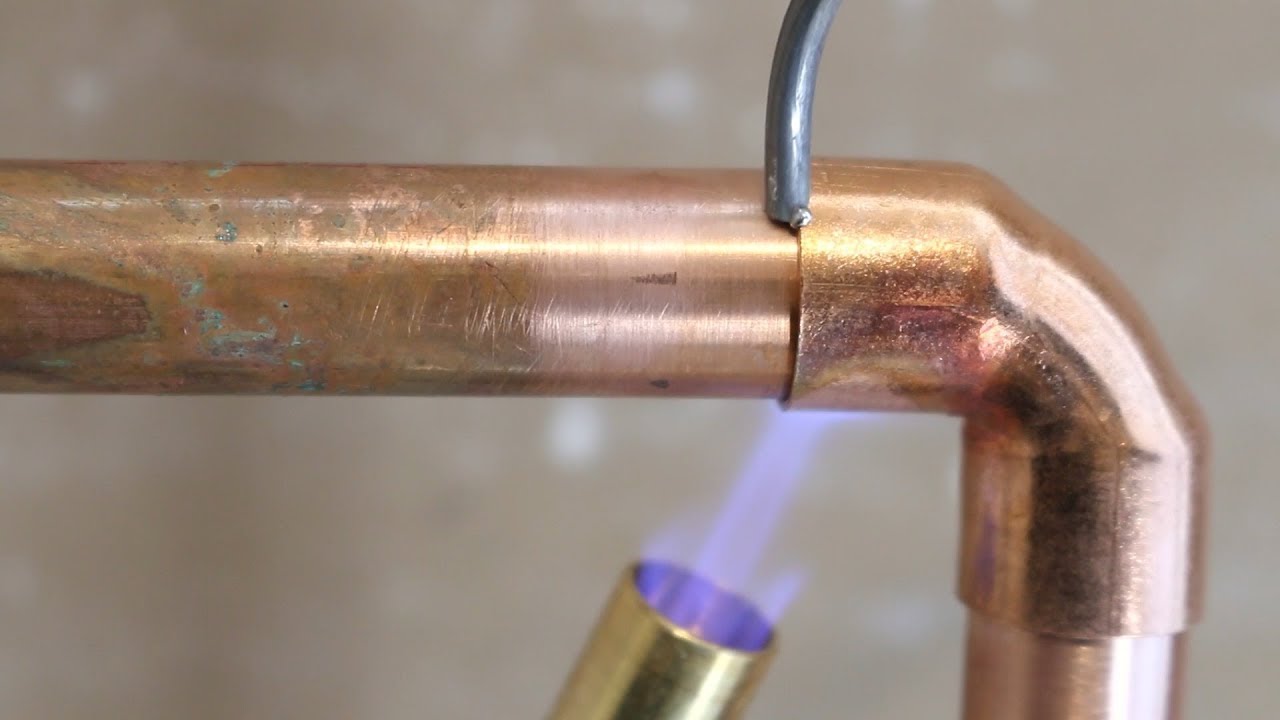

When it starts to smear its close. Besides you need to know how to prepare the pipe and the fitting before you solder them together. Use the torch to heat the outside of the fitting Image 1.

Soldering a copper pipe is just like soldering any two metals. In this video ill go through all the steps on how to properly solder a vertical pipeBecome a member here and get cool perks. If you raise the temperature beyond acceptable levels the copper pipe will significantly heat up.

Flux is generally a jelly containing zinc chloride or sometimes jelly with rosin cleaning components. Push the plug into the pipe with the applicator tube provided. The amount of heat needing to be applied will vary but well deal with that in the next step.

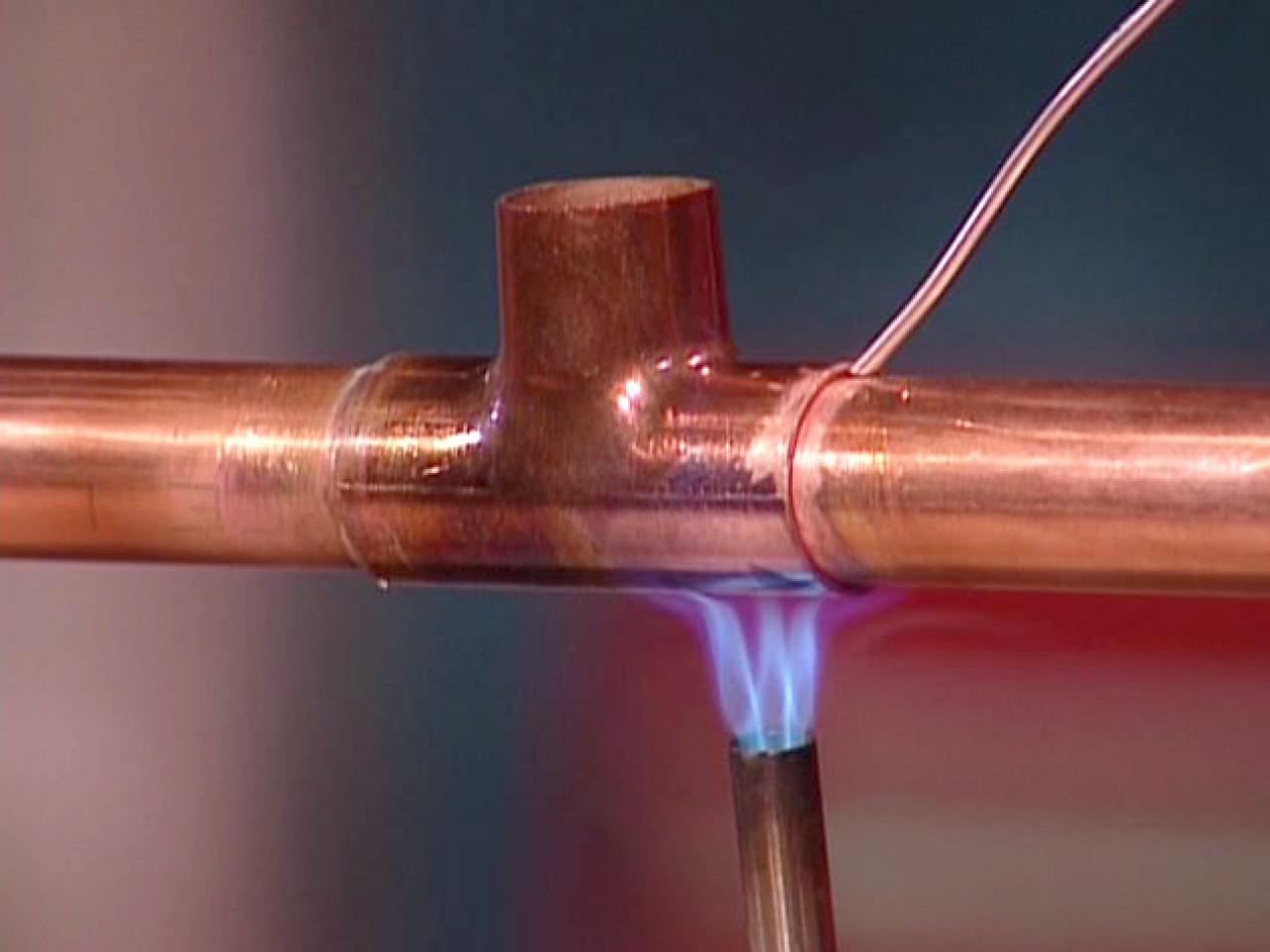

This will damage the flux and render it unusable. Its always best to replace a section of pipe instead of patching a pinhole. Touch the tip of the solder to the joint of the pipe and its fitting Image 2.

Hot enough to melt solder the pipe never apply the flame directly to the solder - apply the flame to the joint and the solder to the joint away from the direct flame. Having the right soldering flux will ensure the copper pipe are strongly soldered. Soldering Flux for Copper Pipes Soldering.

Lead free solder is best for copper pipes carrying drinking water. The main thing is to choose the right kind of flux and solder. After the solder has cooled wipe away any excess making sure that solder completely encircles the joint with no gaps.

A paste-like solution using white vinegar baking soda and salt should be prepared taking equal parts of each should be prepared. Remarkably its easy to solder a copper pipe with water in it. Most of the heat from the torch goes into turning the water to steam so the copper wont get hot enough to melt the solder.

You can either lift the pipe slightly towards the drain point or if you cant move it attach a hose to the end of the pipe you are soldering and blow the water out. It is typically 955 95 tin and 5 antimony or an alloy of tin and a small amount of copper andor silver commonly sold in. Soldering copper pipe requires a relatively large amount of high intensity heat which is why a propane torch is typically used to heat the joint.

You cant use a soldering iron here.

How To Correctly Solder A Copper Pipe 6 Steps With Pictures Instructables

How To Correctly Solder A Copper Pipe 6 Steps With Pictures Instructables

How To Solder Copper Pipe How Tos Diy

How To Solder Copper Pipe How Tos Diy

How To Solder Copper Pipe How Tos Diy

How To Solder Copper Pipe How Tos Diy

/Soldercopperpipe-GettyImages-157186637-597579fec4124400114f2c5f.jpg) Tools Needed For Soldering Copper Pipe

Tools Needed For Soldering Copper Pipe

How To Solder Copper Pipe Draincom

How To Solder Copper Pipe Draincom

How To Correctly Solder A Vertical Copper Pipe Complete Guide Got2learn Youtube

How To Correctly Solder A Vertical Copper Pipe Complete Guide Got2learn Youtube

Solder Flux Avoid These Common Pitfalls When Sweating A Copper Joint 2016 06 13 Plumbing Mechanical

Solder Flux Avoid These Common Pitfalls When Sweating A Copper Joint 2016 06 13 Plumbing Mechanical

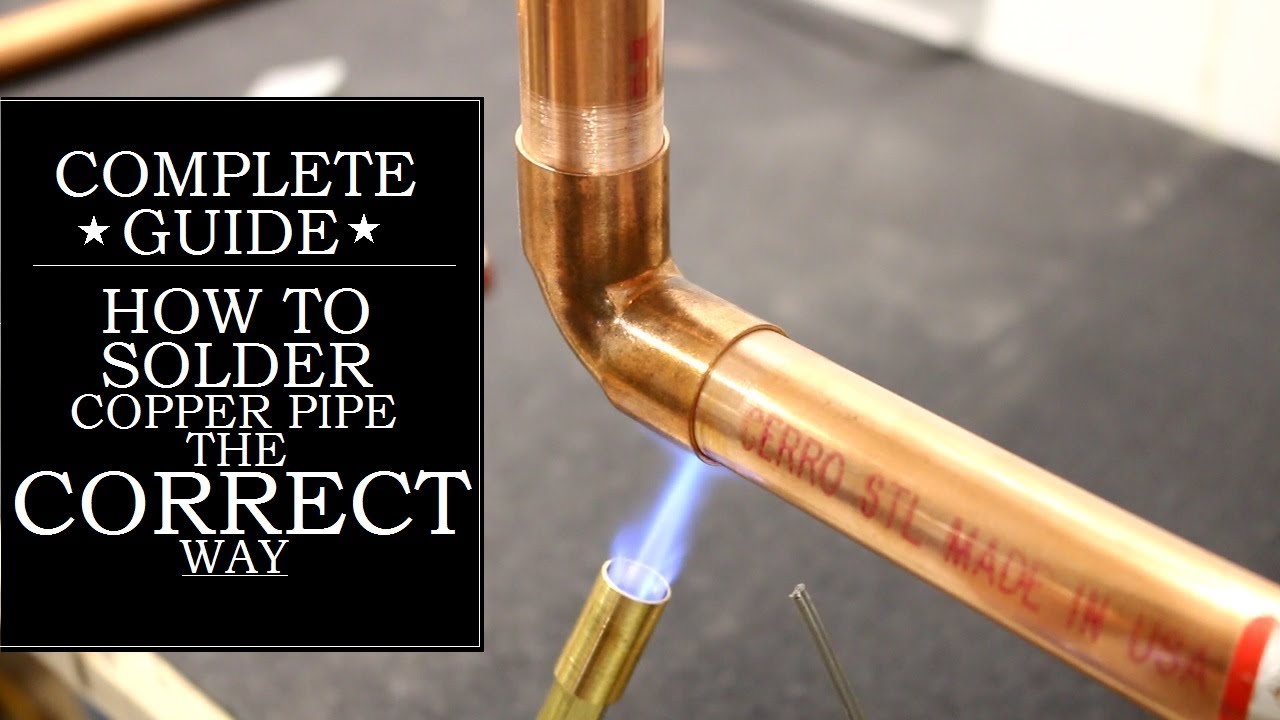

How To Solder Copper Pipe The Correct Way Got2learn Youtube

How To Solder Copper Pipe The Correct Way Got2learn Youtube

How To Solder Copper Pipe Using A Propane Torch How Tos Diy

How To Solder Copper Pipe Using A Propane Torch How Tos Diy

How To Solder Copper Pipe Sweat Copper Pipe Bernzomatic

Comments

Post a Comment